Our Mission

C-10’s mission is to monitor and advocate for the safety of Seabrook Station nuclear power plant in order to protect public health and the environment in Massachusetts, New Hampshire, and beyond.

Radiation Monitoring

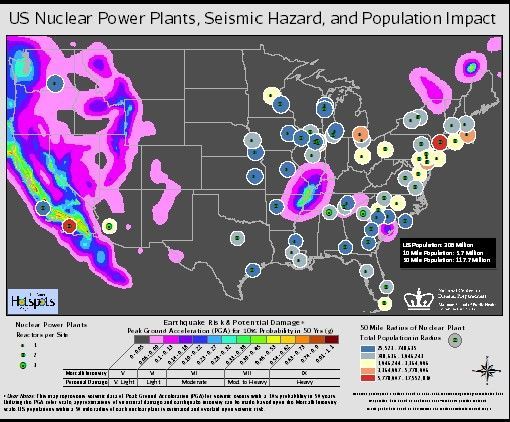

C-10 conducts real-time field monitoring of radiological emissions, wind speed, and wind direction in the communities surrounding Seabrook Station. We have provided this service under contract to the Commonwealth of Massachusetts since 1992.

Education & Community Outreach

Online and at in-person events, we serve as an educational resource and engage in outreach to the public regarding Seabrook Station's health and safety concerns.

Research & Advocacy for Nuclear Safety

We consider ourselves citizen experts on safety at Seabrook Station, and we advocate for upgraded safety and security at the plant. We hold elected and power plant officials accountable for nuclear safety above all else.

Why do we monitor? Why should you care?

Please take a moment to learn about C-10, including why and how we monitor airborne radiation in the communities surrounding Seabrook Station nuclear power plant, a bit about the plant itself, and the ongoing and serious concerns regarding the failing concrete at Seabrook.

Check Out Our Blog